The Revolutionary Impact of 3D Robo Printers in Modern Business

Introduction to 3D Printing Technology

3D printing technology has ushered in a new era of manufacturing and design, enabling businesses to transform ideas into tangible products with unprecedented speed and efficiency. Among the most significant advances in this field is the emergence of the 3D robo printer. This advanced technology not only streamlines production processes but also enhances creativity, reduces costs, and provides endless possibilities for innovation.

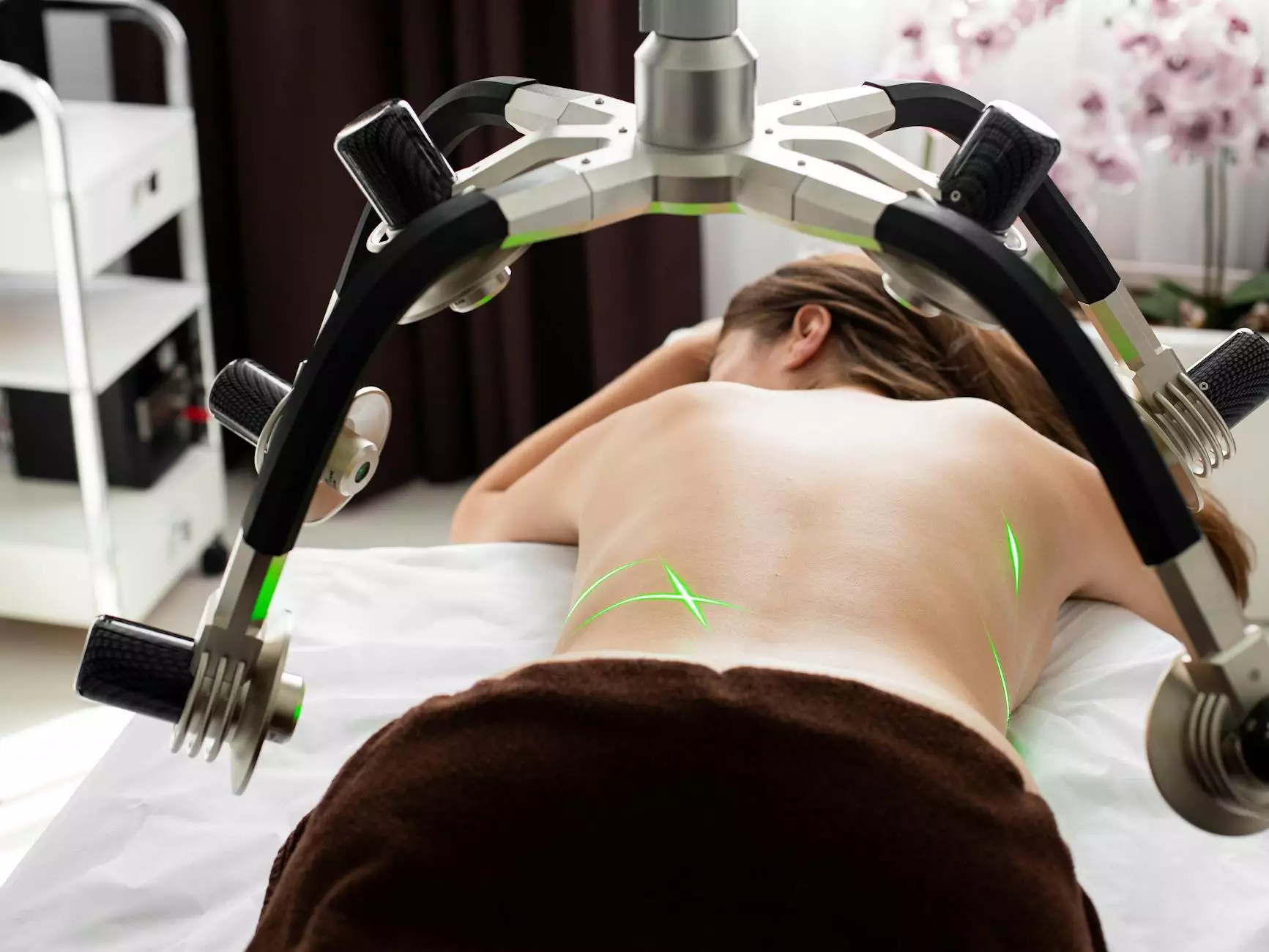

Understanding the 3D Robo Printer

A 3D robo printer refers to a type of 3D printer that utilizes robotic technology to produce three-dimensional objects. Unlike traditional 3D printers, these devices integrate advanced robotics, offering enhanced precision, speed, and versatility. They can print using various materials, including plastics, metals, and even biological materials, catering to a wide range of applications.

Key Features of 3D Robo Printers

- High Precision: 3D robo printers leverage robotic arms that articulate with great accuracy, producing intricate designs that meet exact specifications.

- Speed: These printers can significantly reduce manufacturing time, facilitating rapid prototyping and production.

- Material Versatility: 3D robo printers can use various materials, allowing businesses to select the best option for their specific needs.

- Automation: With integrated robotic systems, these printers can operate autonomously, reducing the need for human intervention.

The Benefits of Implementing 3D Robo Printers in Business

Integrating 3D robo printers into business operations offers numerous advantages that enhance productivity and innovation:

1. Cost Efficiency

3D robo printers dramatically reduce production costs by minimizing material waste and streamlining operations. Businesses can produce parts on-demand, eliminating the need for large inventories.

2. Customization and Personalization

This technology enables businesses to offer customized products tailored to the specific needs of their customers. From bespoke jewelry to custom mechanical components, the potential for personalization is immense.

3. Rapid Prototyping

The ability to quickly create prototypes allows companies to test ideas, gather feedback, and iterate designs faster than ever before. This accelerates time-to-market and enhances overall product development cycles.

4. Sustainability

Many 3D robo printers utilize eco-friendly materials, contributing to more sustainable manufacturing practices. The reduction of waste and energy consumption further bolsters environmental responsibility.

Applications of 3D Robo Printers Across Industries

The versatility of 3D robo printers has led to their adoption across various industries:

1. Aerospace

In the aerospace sector, 3D printing is revolutionizing the production of lightweight and complex components. This not only reduces weight, which is critical for fuel efficiency, but also allows for parts that were previously impossible to manufacture.

2. Healthcare

3D robo printers are making waves in healthcare, from creating prosthetics tailored to individual patients to 3D-printed organs and tissues for research purposes. These innovations are enhancing patient care and driving medical breakthroughs.

3. Automotive

The automotive industry leverages 3D printing for everything from rapid prototyping of components to producing end-use parts. This agility reduces lead times and improves the ability to innovate continuously.

4. Fashion and Jewelry

Fashion designers and jewelers are embracing 3D robo printers for creating unique, intricate designs that are difficult to achieve with traditional manufacturing methods. Personalized jewelry is a growing market that benefits greatly from this technology.

Challenges and Considerations

While the benefits of 3D robo printing are substantial, there are challenges that businesses need to consider:

1. Initial Investment Costs

While prices are decreasing, the initial investment for high-quality 3D robo printers can be significant, especially for small businesses. However, the long-term savings can justify this expenditure.

2. Technical Expertise

Operating and maintaining a 3D robo printer requires a certain level of technical expertise. Companies may need to invest in training staff or hiring specialists.

3. Intellectual Property Concerns

As with any advanced technology, there are risks concerning intellectual property. Businesses must protect their designs and innovations to avoid potential infringement or theft.

Future Trends in 3D Robo Printing

The future of 3D robo printing looks exceptionally promising, with several trends poised to shape the landscape:

1. Advancements in Materials

Continued innovation in materials science will lead to new printable materials, expanding the applications of 3D robo printers across industries.

2. Increased Automation

As automation technology advances, we can expect to see even more sophisticated integrations with 3D robo printers, improving efficiency and reducing human involvement in the manufacturing process.

3. Broader Accessibility

As prices continue to fall, 3D robo printers will become more accessible to small and medium-sized enterprises, democratizing innovation and manufacturing capabilities.

Conclusion

The emergence of the 3D robo printer represents a pivotal advancement in manufacturing technology, enabling businesses to thrive in an increasingly competitive landscape. With advantages extending from cost efficiency to the ability to innovate rapidly, this technology is reshaping industries worldwide. As businesses continue to explore the capabilities of 3D printing, the potential for growth and transformation is boundless.

© 2023 3D Print Wig. All rights reserved. Discover how 3D robo printers can revolutionize your business workflow today!